It is always prudent to consider behavior changes of rain that arise when rain is accompanied with wind. Directional wind will alter the water flow path and the subsequent speed of water run-off.

Water will swiftly transverse a flat vertical wall under regular wind-accompanied conditions, whereas wind flow patterns into a curved wall will follow the curve, suspending the water to a greater extent. The water flow continues to defy gravity and transverses the masonry, until the Coanda effect diminishes and it falls away.

This behavior is more pronounced with high-rise buildings, where a wind speed of 25 m/s can result in the upper top areas of a high-rise building experiencing twice the horizontal rain intensities, regardless of whether the wall elevation is flat or curved. As a rule of thumb, higher wind speeds significantly affect the wetting pattern of walls.

Directional wind will affect the performance of flashings. Water-wash when blown into a leading edge of a traditional running stepped flashing will seep under the edge, and in so doing will be immediately in contact with masonry that is supposed to be kept dry. The masonry is external but becomes internal below the roofline, and once under the flashing, natural gravitation will feed dampness downwardly into the now ‘inside’ wall. If dampness is visible following a storm, checking flashings should be at the top of any check list.

Flush pointing is always recommended around flashings and unlike recessed and angled pointing, flush pointing does not support water channelling along its face. It removes the opportunity for recessed pointing to act as surface conduits, feeding rain into and under flashings. The old 4F rule should always apply: flush finished flashed face.

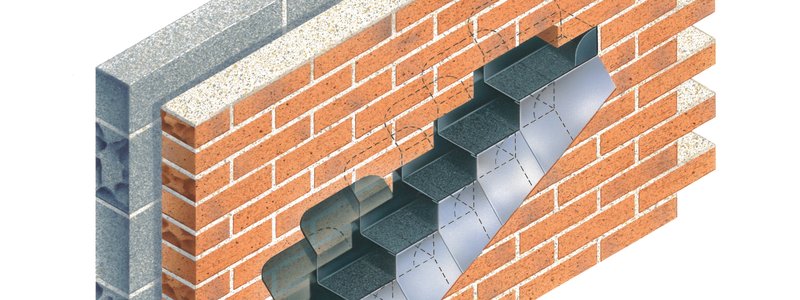

A proven reliable approach is to use preformed cavity trays with ready-shaped flashings already bonded on. The individual flashings overlap and this results in a protective second layer being in place at every step. If wind-driven rain challenges the leading edge, direct contact with masonry is prevented as the under-flashing arrests the water. Consequently, this type of tray manufactured by the longest-established specialist – Cavity Trays Ltd, and known as the Type X for gable abutments, is favoured, especially on exposed sites. With the current weather changes nationwide, who knows where exposed areas in the UK start and finish?

Approved Type X Cavitrays – information at www.cavitytrays.co.uk